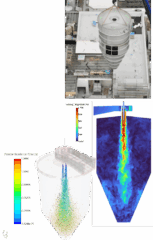

Spray drying is a complex multiphase process used to convert liquid feed into dry powder in industries such as food, pharmaceuticals, and chemicals. This thesis, conducted in close industrial collaboration, aims to investigate flow in industrial spray dryers. The CFD dataset aims to be lay foundation for a digital twin of these complex devices. The focus lies on understanding the internal flow structures, turbulence behaviour, droplet trajectories, evaporation–condensation dynamics, and particle–wall interactions, all of which critically influence product quality, efficiency, and explosion safety. Inside large spray towers (height ~20 m), atomised droplets undergo rapid evaporation, heat exchange, and particle formation under strongly turbulent and recirculating flow conditions. Understanding these coupled processes remains a major challenge due to the wide range of spatial (mm–m) and temporal (ms–hours) scales involved and the transient interaction between air flow, droplets, and thermal gradients. In the previous phase of this work, validated single-phase (dry-air) CFD simulations were carried out to characterise the internal flow field, turbulence behaviour, velocity distributions and multiphase phenomena within the industrial-scale dryer. Building upon these results, this thesis focuses on the advancement of the multiphase modelling framework towards a more realistic representation of the full drying process.

Tasks

- Multiphase CFD simulations for evaporation and condensation modelling.

- Conduct transient simulations under realistic process conditions.

- Design of Experiments using different operating conditions.

- Data extraction, post-processing, and statistical evaluation of CFD data.

- Analyse particle drying behaviour, residence time, and wall interaction.

- Compare simulation trends with available experimental data.

Requirements:

- Strong background in Fluid Mechanics, CFD and Multiphase Flow.

- Experience with CAD and CFD software (preferably Star-CCM+).

- Programming and scripting skills in C++ or Python, Java (macros).

- Good communication skills in English (German advantageous).

- Self-motivated and capable of independent research work.

What We Offer:

- Interdisciplinary research environment bridging industry and academia.

- Hands-on experience and training on industrial CFD software (Star-CCM+).

- Application of fluid dynamics in industrial processes

Beginn: ab sofort

Supervisors:

Prof. Dr. habil. Andreas Wierschem

Room: Room 0.222

- Phone number: +49 9131 85-29566

- Email: andreas.wierschem@fau.de