Wind tunnels have long been used in aerodynamics to study airflow behaviour, pressure distribution, and drag characteristics under controlled and repeatable conditions. They provide invaluable insight into how air moves around objects such as aircraft, vehicles, or flow sensors, allowing precise validation of theoretical and numerical models. In real-world applications such as spray drying, process engineering, and UAV or aircraft operations, flow sensors often operate in dusty, humid, or particle-laden conditions that lead to fouling, condensation, and signal drift. To investigate and overcome these challenges, a new multiphase wind tunnel is being developed in-house as part of an industrial collaboration for aerodynamic probe testing.

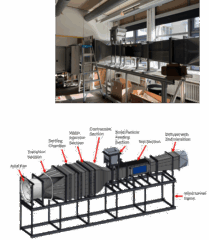

The tunnel design is aimed to generate controlled particle-laden and humid flows conditions, enabling systematic studies on probe fouling, deposition mechanisms, and purge-cleaning behaviour. The setup is an Eiffel-type open return tunnel with flow conditioning, contraction, and a transparent test section made of scratch-resistant quartz glass—prepared for future PIV (Particle Image Velocimetry) measurements. A particle injection unit with a hopper and dosing mechanism enables solid or liquid aerosol introduction, while a humidity and water-injection system allows fine control of moisture content. The outlet section will integrate a filtration and expansion box to ensure safe particle separation and operation. This system will serve as a universal test bench for evaluating Pitot tubes, Kiel probes with integrated humidity sensors and multi-hole fast-response sensors under reproducible dirty environmental conditions.

Tasks

- Concept development of humidity, particle dosing, filtration subsystems

- CAD design, component selection, preparing manufacturing drawings.

- Coordination with technical staff at all stages.

- Support industrial partner on flow control and data-acquisition system for flow, humidity, fouling.

- Execution of experiments with humid and particle-laden flows

Requirements:

- Strong background in mechanical engineering, fluid mechanics.

- Experience with CAD software (preferably PTC Creo or similar).

- Good understanding of manufacturing processes and assembly.

- Interest in laboratory work and experimental setups.

- Hands-on approach to design, testing, and troubleshooting.

- Ability to work independently and in a multidisciplinary team

- Good communication skills and structured documentation style

Beginn: ab sofort

Supervisors:

Prof. Dr. habil. Andreas Wierschem

Room: Room 0.222

- Phone number: +49 9131 85-29566

- Email: andreas.wierschem@fau.de